Over 60 factories got Anysort Tea Color Sorters repaired

Project Description

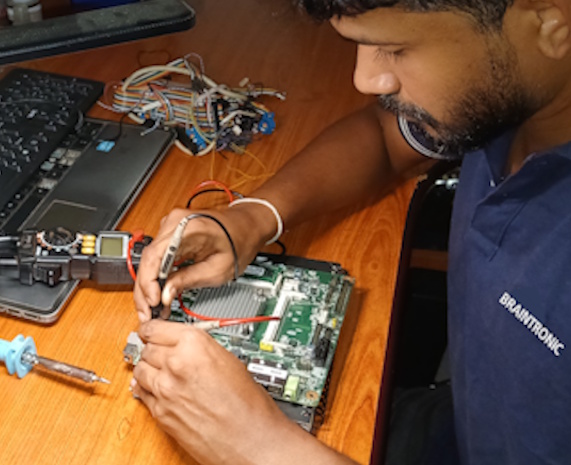

Braintronic established itself as a trusted partner for tea factories across Sri Lanka in maintaining and repairing Anysort tea color sorters. Over the past few years, we repaired and serviced more than 50 Anysort tea color sorters, restoring them to peak operational efficiency.

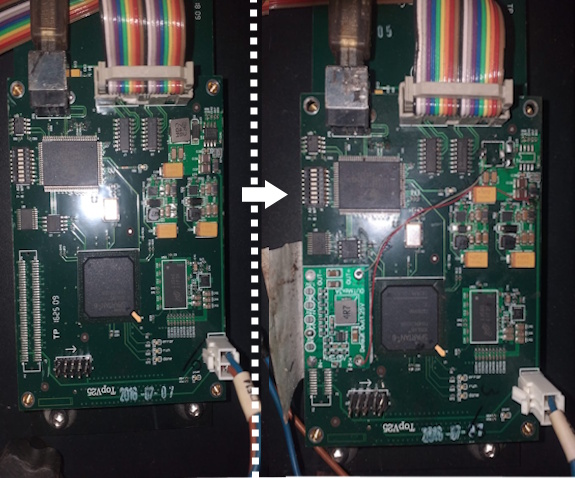

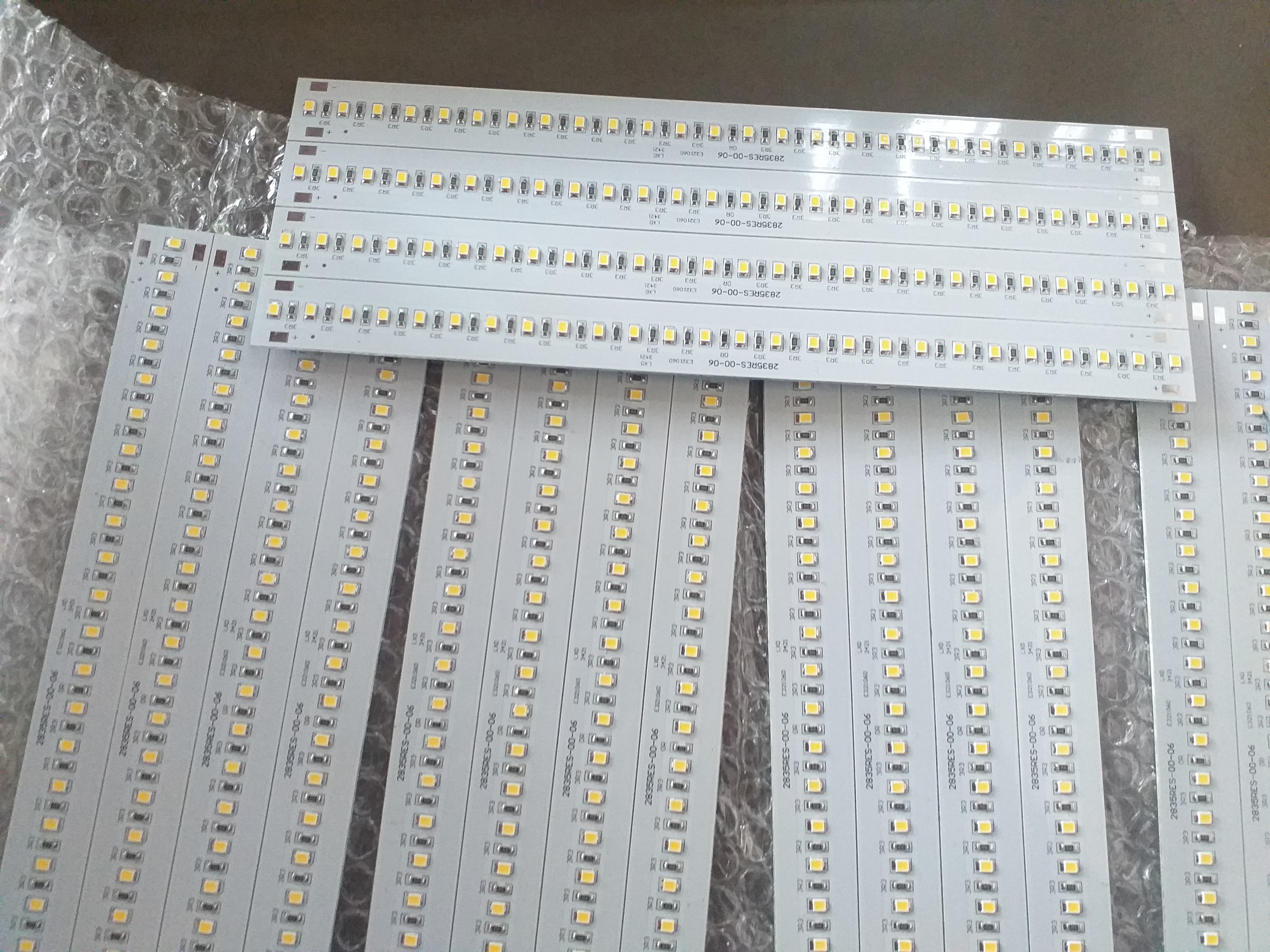

Our highly skilled technical team used advanced diagnostic tools and genuine spare parts to ensure precise calibration, improved sorting accuracy, and reduced downtime. By combining technical expertise with a deep understanding of the tea industry’s demands, we helped factories maintain high product quality while minimizing operational disruptions.

Our expertise in Anysort repairs extended to many leading tea factories, including:

- Devonia Tea Factory – Full overhaul and calibration of sorting system.

- Fortune Tea Factory – Replacement of defective sensors and software update.

- Allerton Tea Factory – Mechanical refurbishing and belt alignment.

- Handugala Tea Factory – Emergency repair during peak production season.

- Kithulgala Tea Factory – Optical system cleaning and parameter optimization.

Through these projects, Braintronic built a reputation for delivering fast, reliable, and factory-ready solutions that minimized downtime and maximized output quality.

The Challenge in Installation

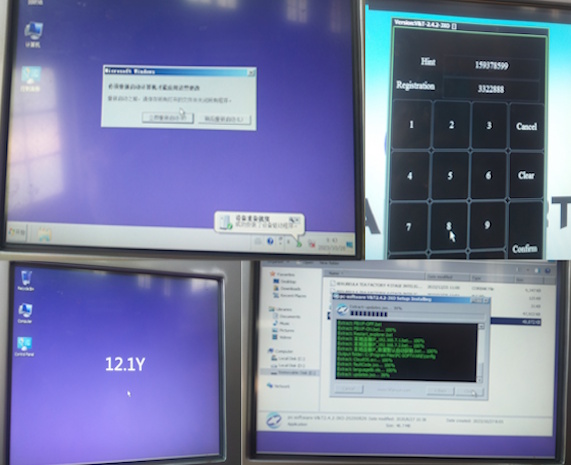

Installing and calibrating an Anysort tea color sorter was not simply a matter of placing it on the production floor. The key challenges we faced included:

- Alignment & Calibration – Ensuring perfect optical alignment for maximum sorting accuracy.

- Software Configuration – Adjusting settings to suit different tea grades and types.

- Space Limitations – Working within the restricted layouts of older tea factories.

- Electrical Stability – Maintaining reliable voltage and protection from surges.

Our team developed strategies to overcome these challenges, ensuring each machine operated at its full potential from day one.

— Factory Owner, Kithulgala Tea Factory

The Final View of Project

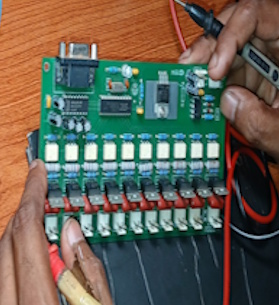

After each repair or installation, every Anysort tea color sorter underwent a rigorous final quality check, which included:

- Optical inspection accuracy testing.

- Throughput capacity verification under real production conditions.

- Fine-tuning for specific tea leaf sizes and colors.

The final result was a fully functional, highly accurate sorter that delivered consistent results for years to come.