“Over 50 Tea Factories Modernized with VFD Solutions to Cut Energy Expenses”

Project Description

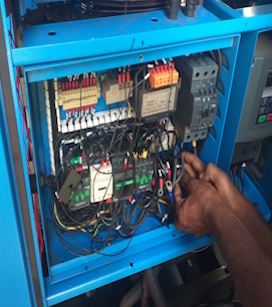

Braintronic successfully completed VFD installations for compressors at several well-known tea factories across the region, helping improve energy efficiency, reduce operating costs, and enhance the reliability of compressor systems.

Each installation involved custom tailoring of the VFD system to the specific compressor brand and adapting to each factory’s unique layout, ensuring seamless integration with existing equipment.

Some of the key projects included:

- Neluwa Madagama Tea Factory – Linghein L22 (Anysort)

- Hingalgoda Tea Factory – Assence FU22 (Meyer)

- New Gamini Tea Factory – Mack Power 22 (Meyer) & Linghein L18.5 (Anysort)

- Gunawardana Tea Factory – Linghein L15 (Anysort)

- Galagawa Tea Factory – MIKOVS (Braintronic)

- Naindawa Tea Factory – Kaeser (Nikini Automation)

- Etabagahawila Tea Factory – Kaeser (Nikini Automation)

- Mahesland Tea Factory – Kaeser (Nikini Automation)

- Danawala Tea Factory – Linghein L22 (Anysort)

The Challenge in Installation

Installing VFDs in active industrial environments often presented complex challenges, which our teams successfully addressed, such as:

- Compatibility issues between older compressors and modern VFD systems.

- Space limitations in existing electrical rooms, requiring re-layout of equipment.

- Voltage fluctuations in tea factories, necessitating stabilizers and protective relays.

- Dust and heat issues inside compressor cabins – For example, at Neluwa Madagama Tea Factory, a major risk was identified where compacted machines operating in a single enclosed room exposed VFD units to excessive dust and heat. This created the potential for overheating or even burning of the drive units.

Our engineers not only resolved the problem by improving airflow and insulation but also instructed the factory managers on best practices, emphasizing that VFD units must be regularly cleaned and operated in well-ventilated environments to prevent similar failures in the future.

Gunawardana Tea Factory

“The VFD installation on our Linghein L15 compressor significantly improved performance and really helped reduce our electricity bills. Braintronic handled the integration seamlessly, ensured minimal disruption to production, and provided our staff with clear operational guidance. We are so satisfied that we are planning to install VFDs on our other compressors soon.”

— Factory Engineer, Gunawardana Tea Factory

The Final View of Project

The installation of VFDs for compressors consistently delivered measurable improvements across all completed projects. Factories reported energy savings of around 20–35%, along with noticeably lower electricity costs. The controlled operation of compressors reduced wear and tear, extended equipment life, and minimized noise levels. In addition, the systems enabled better remote monitoring and automation, which improved overall management and supported predictive maintenance planning.