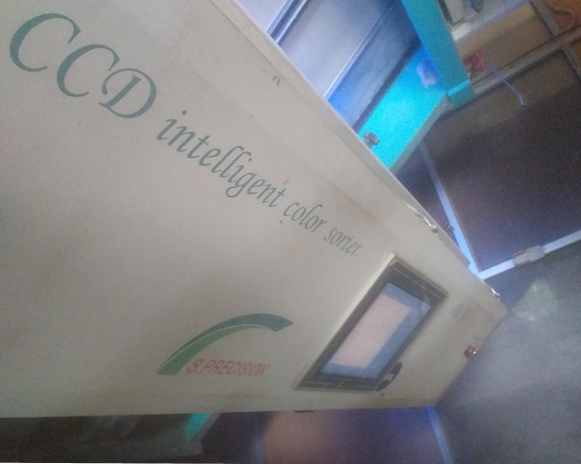

Over 60 rice mills got Taiho rice color sorters repaired

Project Description

Braintronic successfully repaired and serviced multiple Taiho rice color sorters across Sri Lanka, restoring them to full working condition and enhancing their accuracy. Our technical teams combined advanced diagnostic methods with precision repairs to bring machines back into peak performance.

Some of the key projects included:

- Nileeka Rice Mill – Taiho Color Sorter

- Kawmadi Rice Mill – Taiho Color Sorter

- Sewmini Rice Mill – Taiho Color Sorter

These were only a few among the many successful Taiho repair projects completed by our team.

The Challenge in Installation

Each rice mill faced unique operational challenges during our interventions:

At Nileeka Rice Mill, the machine had severe faults including a non-booting display, malfunctioning grain feed, and misfiring ejectors. The challenge was to reprogram the control systems while restoring precise grain flow and ejector timing.

At Kawmadi Rice Mill, the sorter suffered from sorting inconsistencies due to LED failure, blocked valves, and sensor dust contamination. Ensuring reliable optical accuracy required careful cleaning, LED replacement, and full recalibration.

At Sewmini Rice Mill, power failures and overheating threatened system stability. The challenge was to enhance cooling while repairing damaged power modules and restoring ejector functions.

“Braintronic’s repair on our Taiho sorter solved long-standing problems we faced. The reliability has been restored, and false rejects are now minimal. We appreciate their professional service and plan to continue relying on their expertise.”

— Manager, Kawmadi Rice Mill

The Final View of Project

Through these repair projects, Braintronic:

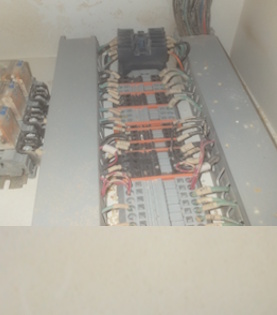

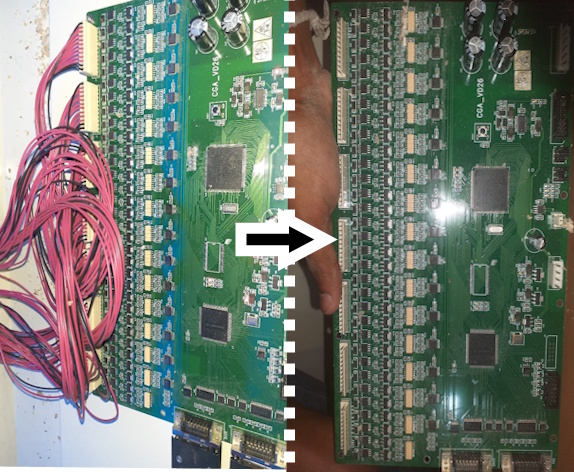

- Reprogrammed control panels and recalibrated optical cameras

- Repaired ejectors, pneumatic systems, and vibrators

- Replaced faulty power modules and upgraded cooling systems

- Restored precise sorting accuracy with reliable machine stability

All color sorters were fully tested and handed over after achieving stable, high-quality sorting.