Over 60 factories got NANTA tea color sorters repaired

Project Description

Braintronic successfully repaired and serviced over 60 NANTA Tea Color Sorters across Sri Lanka, restoring machines to peak performance and extending their service life. Below are only a portion of the projects completed. Many more NANTA 7000 and NANTA 9000 machines were restored to full working condition.

- Mathurata Plantation PLC – Gonapitiya Estate, Nuwara Eliya – NANTA 7000 Tea Color Sorter Repair

- Willie Group Tea Factory – Andaradeniya Estate (Pvt) Ltd, Neluwa – NANTA 5000 Color Sorter Repairing

- Kumudu Tea Factory – Aluthgama – NANTA 9000 Repairing

- Sanora Tea Factory – Ratnapura – NANTA 7000 Display Replacing, NANTA 9000 Repairing

- Kukulegaga Tea Factory – Kalawana – NANTA Expedia Color Sorter Service

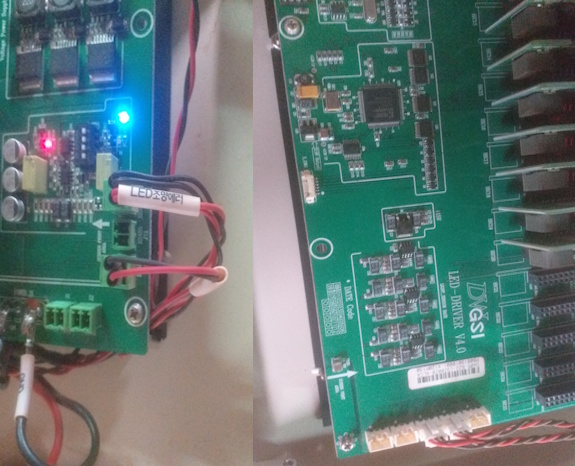

- Batuwangala Tea Factory – Andaradeniya Estate (Pvt) Ltd, Neluwa – NANTA 7000 LED Replacing

- Niwitigala Tea Factory – Andaradeniya Estate (Pvt) Ltd, Neluwa – Vibrator Coil for NANTA 7000

- Karagoda Tea Factory – Galle – NANTA 9000 Color Sorter Tubing & Repairing

- Galahitiya Tea Factory – Parakaduwa – NANTA 7000 Color Sorter Repairing & HMI Display Repairs

- Iluktenna Tea Factory – Bogawanthalawa Estate PLC, Deraniyagala – NANTA 7000 & 9000 Color Sorter Repairs

- Kurupanawa Tea Factory – Tea Smallholder Factories PLC, Colombo – NANTA 9000 Machine Repairing

- Kirkoswald Tea Factory – Madolsima Plantation PLC, Norwood – NANTA 7000 Color Sorter Repairing

- Handugala Tea Factory – Deiyandara – NANTA 7000 & DVR-3HJ Color Sorter Repairing

- Ruhunu Tea Factory – Andaradeniya Estate (Pvt) Ltd, Neluwa – NANTA 7000 Color Sorter Repairing

Challenges in Installation

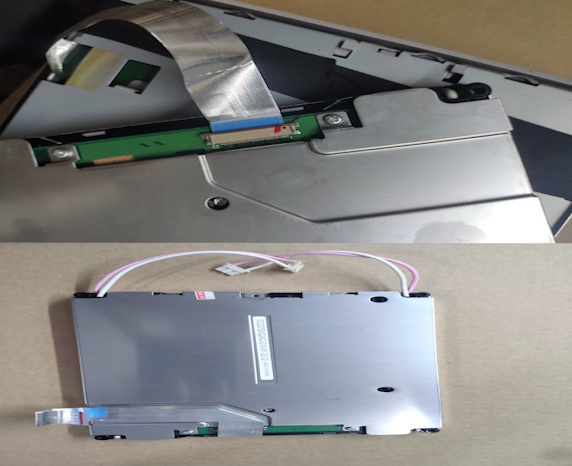

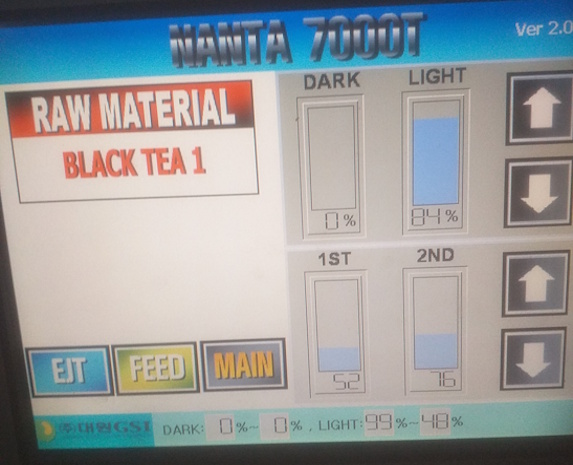

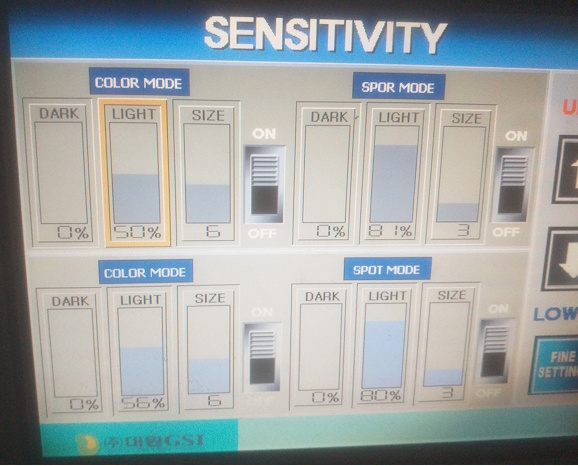

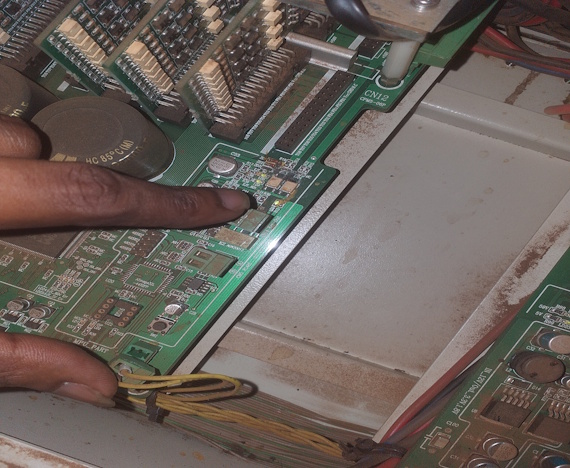

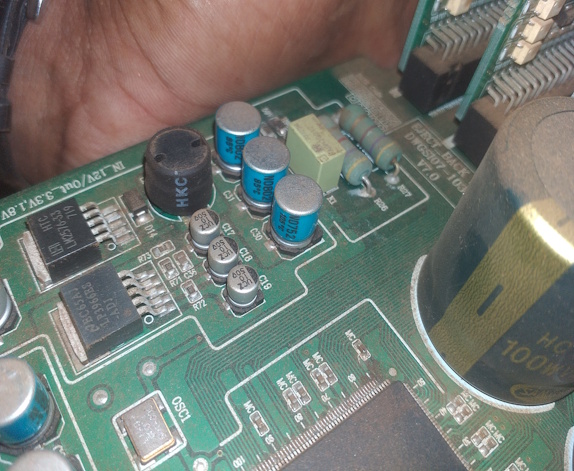

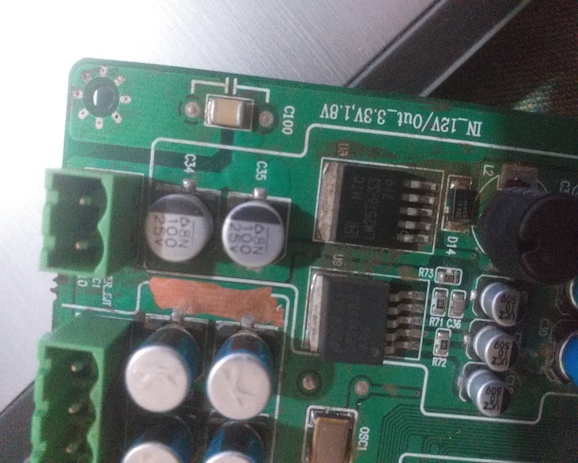

Most of the machines had been operating for several years without major servicing, leading to frequent breakdowns, damaged displays, worn-out tubing, defective vibrator coils, and issues in the air dryer systems.

One of the biggest challenges was that some factories had limited downtime, requiring Braintronic engineers to complete the work efficiently without interrupting daily tea processing. Additionally, sourcing genuine spare parts for older NANTA models demanded technical expertise and precise adjustments.

We were struggling with continuous breakdowns of our NANTA 7000 machine, which affected our production quality and speed. Braintronic repaired it within a short time and restored the machine to excellent working condition. Their professionalism and technical knowledge gave us confidence, and now our sorter is running more reliably than before.

— Factory Owner, Sanora Tea Factory, Ratnapura

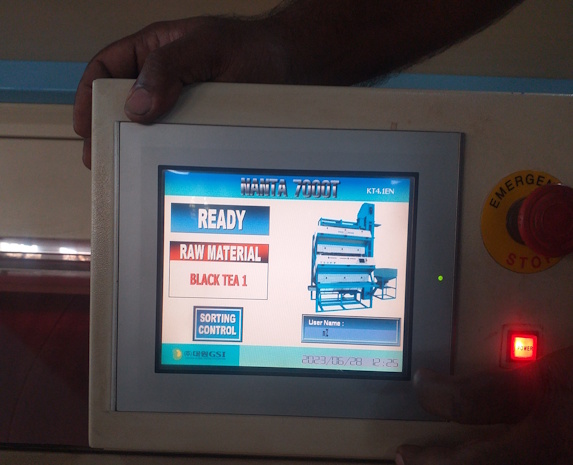

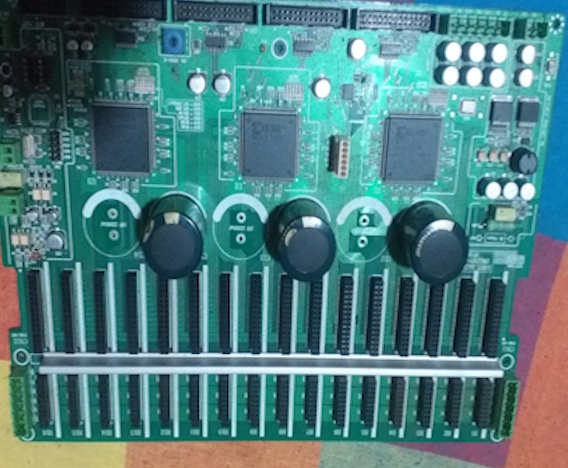

The Final View of Project

By the completion of this project, more than 60 factories had their NANTA Tea Color Sorters restored, significantly reducing downtime and improving sorting accuracy. The repairs extended the lifespan of existing machines, providing cost savings to factory owners while maintaining the high standards of tea grading.

Braintronic’s skilled engineering team ensured every machine was serviced to factory-level standards, proving once again that timely preventive maintenance and expert repair can keep even older NANTA machines performing at peak efficiency.