Over 60 factories got Meyer tea color sorters repaired

Project Description

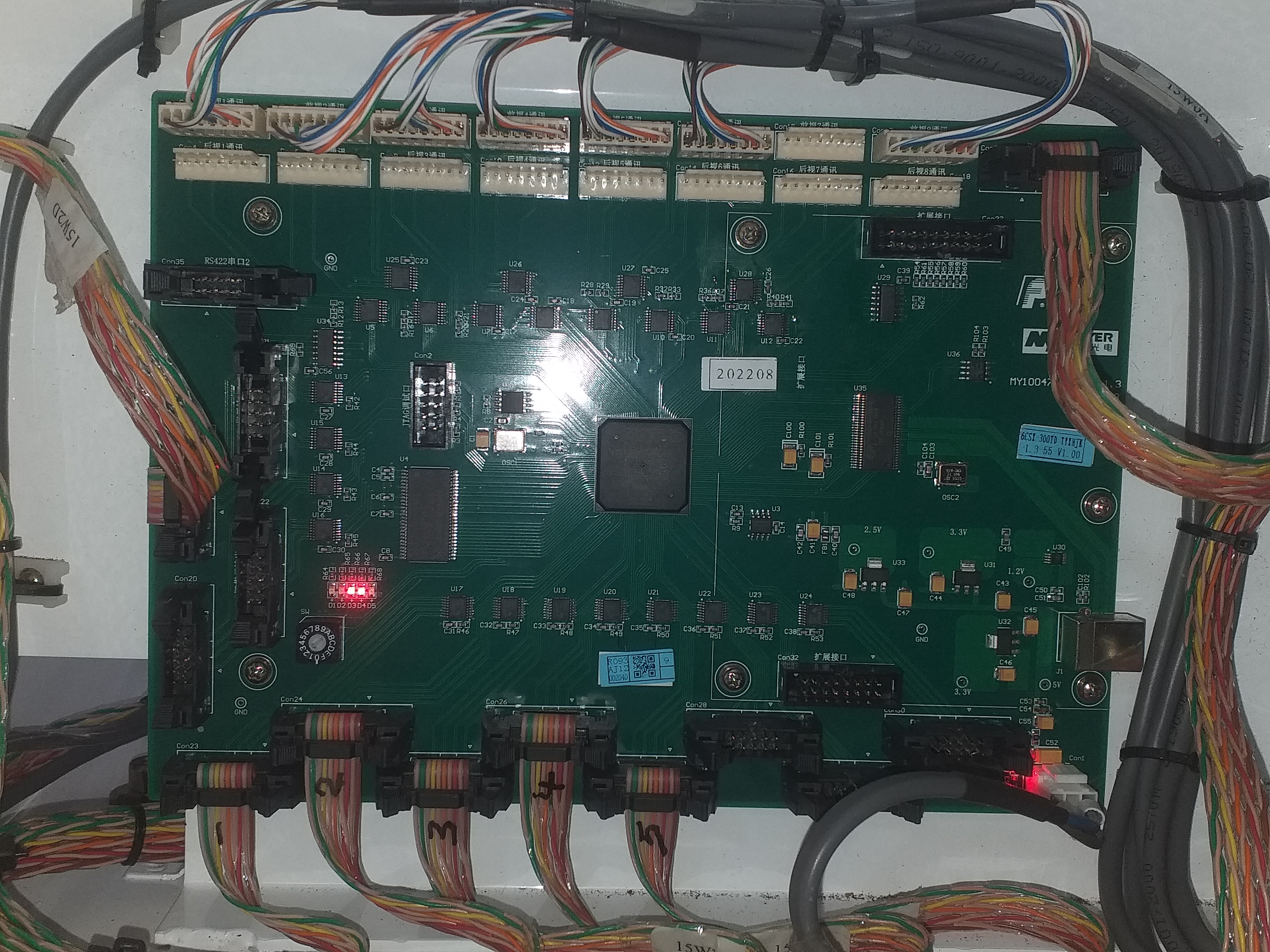

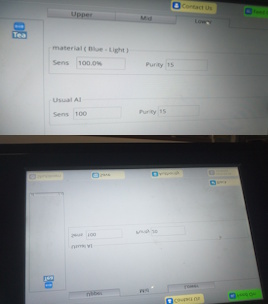

Braintronic successfully completed the repair and restoration of Meyer Tea Color Sorters across several factories in Sri Lanka. These machines are critical in the tea industry for maintaining leaf quality, grade separation, and production efficiency. Over time, many units developed faults in their control boards, displays, and internal mechanisms due to heavy usage and lack of preventive servicing.

- Iddamaldeniya Tea Factory – Wanduramba

Meyer Color Sorter Repairing (main board and sensor adjustments) - Dumbara Tea Factory

Meyer 4-Stage Board Repair (board-level restoration and calibration for long-term stability)

These are only a few highlights of Meyer Tea Color Sorters repaired and serviced successfully across several factories in Sri Lanka.

The Challenge in Installation

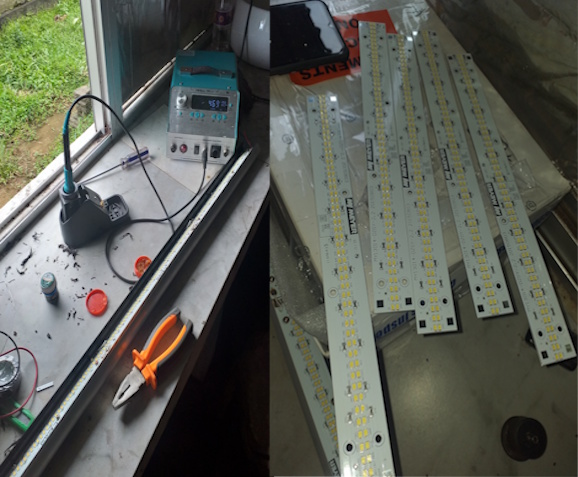

- Complex Electronics: Meyer machines use advanced multi-stage boards that are highly sensitive. Repairing and restoring these boards required deep expertise in board-level troubleshooting.

- Calibration Issues: After repair, the machines needed highly precise recalibration to match the fine standards required in tea grading.

- Downtime Pressure: Many factories had very limited downtime for maintenance, which meant Braintronic engineers had to deliver results quickly without affecting production schedules.

- Component Availability: Some spare parts for older Meyer models were difficult to source, requiring specialized technical adjustments and restoration.

Despite these challenges, Braintronic ensured every machine was restored efficiently and with minimal disruption to tea production.

Our Meyer Tea Color Sorter had been unreliable for months, and breakdowns were slowing down production. Braintronic’s team diagnosed the issue quickly, repaired the faulty board, and brought the machine back to full performance. The improvement in sorting quality was immediate. Their expertise and professionalism gave us complete confidence in their service.

— Factory Owner, Iddamaldeniya Tea Factory, Wanduramba

The Final View of Project

By project completion, Braintronic had successfully restored several Meyer Tea Color Sorters to factory-level standards of performance.