Imported and Distributed Essential Machinery Spare Parts for Tea Factories

Project Description

To meet the growing demand for reliable maintenance and part replacement across Sri Lankan factories, Braintronic imported premium-quality spare parts for air compressors and air dryers. These components were critical to ensuring the long-term efficiency, safety, and uptime of industrial systems.

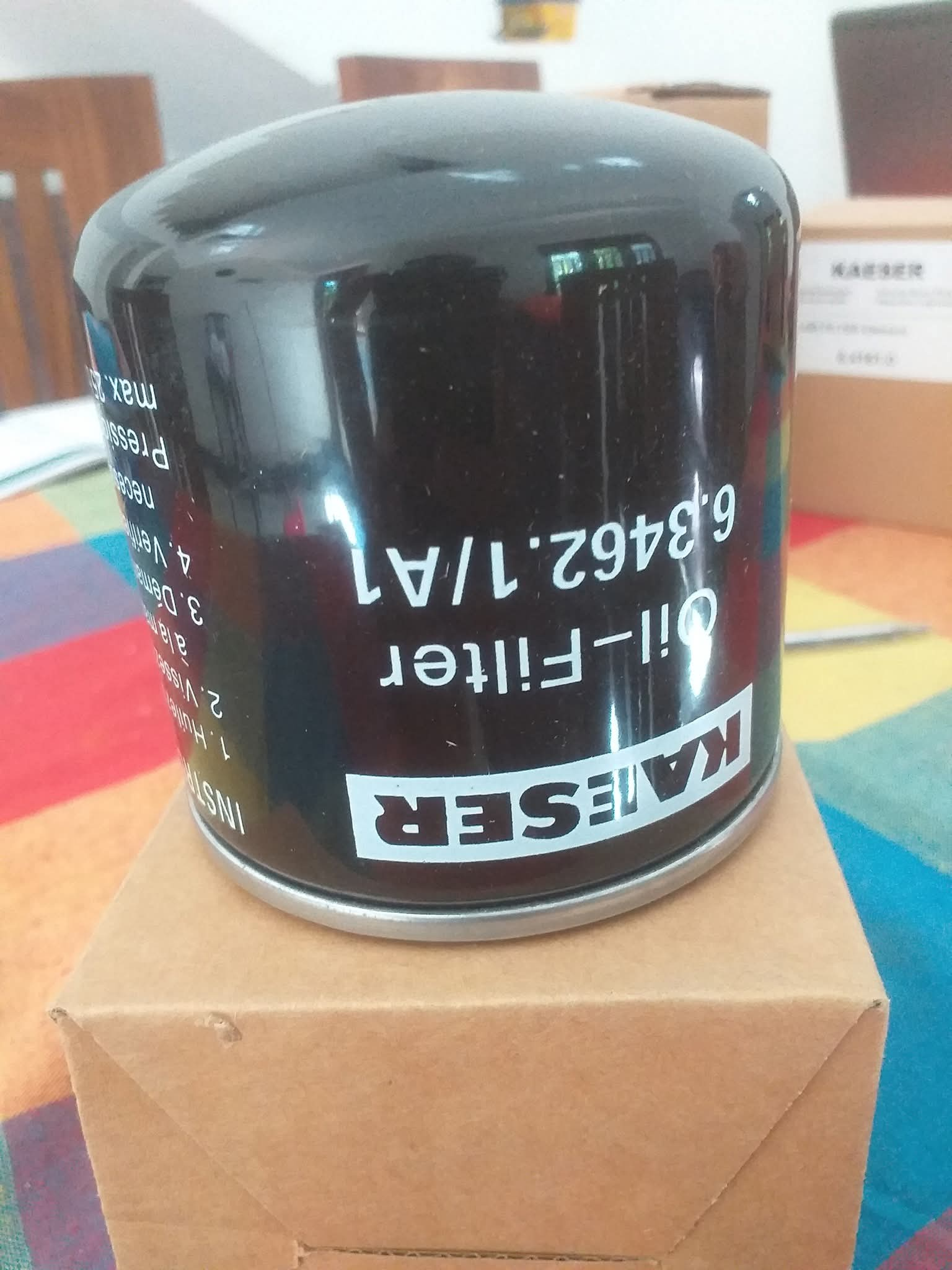

Our spare parts inventory covered a wide range of global brands, including KEASER, Daifrom, Meyer, Linghein, Jaguar, Fusheng, and BOGR, offering factory-grade performance for both modern and legacy equipment.

- Oil Separators

- Oil Filters & Air Filters

- Non-Return Valves & Temperature Sensors

- Display Units for Air Dryers

- Seal Kits, O-Rings, and Oil Seals

- Line Filters for Compressed Air Systems

All items imported were OEM-certified or high-grade aftermarket, carefully selected for durability, compatibility, and performance in tropical industrial environments.

Special Highlights of Imported Spare Parts:

- KEASER Compressors: ASK 32, ASD 37, DSD 72 – oil separators, oil filters, air filters.

- LINGHEIN Compressors: LS15/8, L22/8 – oil separators, filters.

- FUSHENG Screw Compressors: 22kW units – oil separators.

- BOGR Compressors: Line filters 1/50FP, 1/50A.

- Universal Filter Elements: Air filter 6.3464.1, oil filter WD962, separator element SCR 25200007-005.

- Daifrom, Jaguar, Meyer, and Others: Jaguar 22kW oil seal, Meyer 22kW filter sets, LS15 oil seal and non-return valves, display panels, temperature sensors & O-ring kits.

- Premium Oils: Shell Corena S3 R 46 – imported from Korea, long-life and high-efficiency rotary compressor oil.

Braintronic also provided compatibility consultations, ensuring each part matched the client’s equipment, reducing the risk of incorrect installations and improving operational reliability.

Braintronic supplied all the spare parts we needed for our compressors and air dryers with exact-fit precision. Their parts reduced downtime, improved efficiency, and extended the life of our equipment. Their technical support made installation seamless.

— Factory Owner, Methum Lanka Rice Mill

The Final View of Project

Through the import and supply of high-grade spare parts, Braintronic enabled factories to:

- Obtain exact-fit, high-performance components for a wide range of compressor and dryer brands.

- Maintain ready stock of frequently failing parts to minimize downtime.

- Receive technical guidance for proper installation and maintenance.

- Reduce breakdowns and improve energy efficiency.

- Extend equipment lifespan with reliable filtration and sealing systems.

The Challenge in Installation

- Model-Specific Fitment: Each part had to match exact compressor model specifications, including thread sizes and pressure ratings.

- High Heat & Humidity: Parts needed to endure Sri Lanka’s demanding climatic conditions.

- Brand Diversity: Serving factories with different compressor models required maintaining a large, varied inventory.

- Urgent Breakdowns: Ready availability was essential to prevent downtime during peak operations.

- Counterfeit Risk: Ensuring all parts were genuine or high-grade alternatives was critical.

Braintronic overcame these challenges by curating each shipment, stocking rare and hard-to-find parts, and offering technical support for installation.