Over 60 factories got SENVEC tea color sorters repaired

Project Description

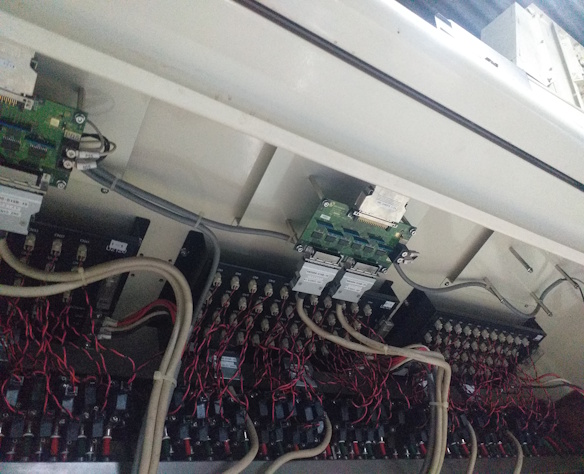

Our engineering team successfully completed several Senvec tea color sorter repair projects across leading Sri Lankan tea factories. Each assignment was handled with precision to restore reliability, improve efficiency, and extend the service life of the machines.

These are only a few examples of the many types of repairs we carried out at factories such as Allerton Tea Factory (Rakwana), Batuwangala Tea Factory (Neluwa), Thalapalakanda Tea Factory (Deniyaya), and Halwitigala Tea Factory (Colombo):

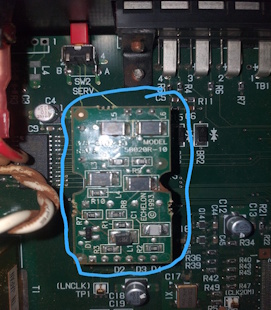

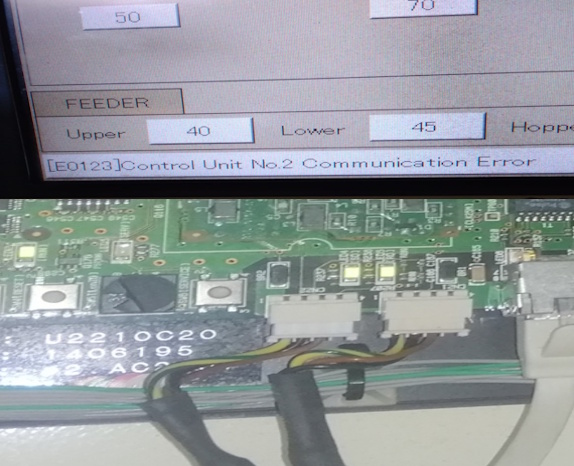

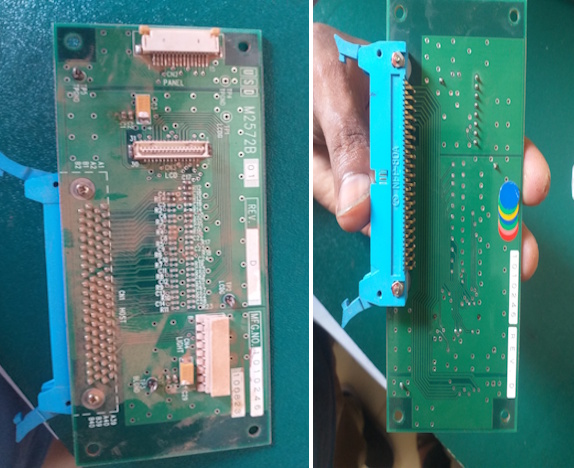

- Control board repairs

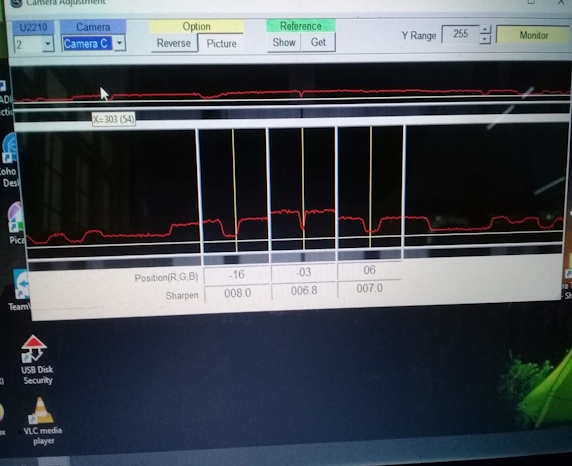

- Correcting camera alignments

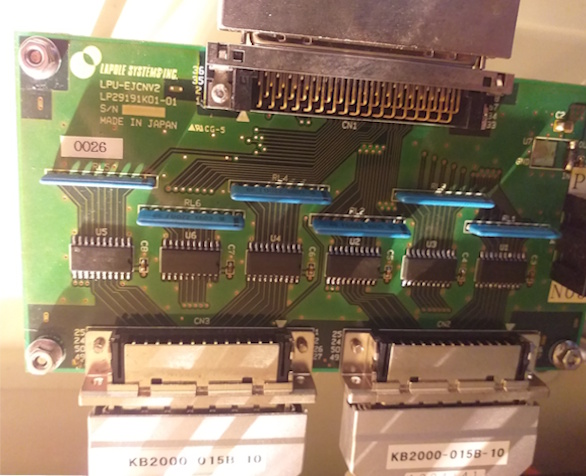

- Repairing communication errors

- Replacing LEDs

- Senvec DVR display and touch screen replacements

- Repairing Senvec feeder errors

Each repair was followed by calibration and final testing to ensure the machines returned to factory-level performance.

The Challenge in Installation

The main challenge we faced was the long-term wear of critical parts. Many machines had been operating for years with little maintenance, leading to frequent breakdowns and downtime. Original spares were sometimes unavailable, which required us to engineer custom-fit solutions to keep repairs on schedule. Despite these difficulties, our team successfully completed the work while allowing factories to continue production with minimal interruptions.

"Our Senvec color sorter had frequent issues, from feeder errors to display failures, causing interruptions in production. Braintronic’s team quickly identified the problems and restored the machine to full working order. Their technical knowledge and commitment to minimizing downtime impressed us. Today our sorter runs as reliably as a new one."

Factory Manager, Allerton Tea Factory

The Final View of Project

All repaired Senvec machines were restored to smooth, stable, and reliable performance, delivering precise sorting accuracy and reduced downtime. Factory owners reported improved workflow, consistent tea quality, and renewed confidence in their equipment. These projects highlighted our ability to deliver fast, reliable, and long-lasting repair solutions for Senvec color sorters, keeping Sri Lanka’s tea factories operating at peak performance.