Over 60 factories got Timing Tea Color Sorters repaired

Project Description

Our engineering team successfully carried out several Timing tea color sorter repair projects across Sri Lanka, restoring machines to factory-standard accuracy and reliability. Each project was approached with a focus on reducing downtime, improving performance, and ensuring continuous production in the tea factories we served. The machines were thoroughly inspected, faulty modules were repaired or replaced, and final calibrations were performed to achieve optimal sorting precision.

These are only a few of our doings: at Rasilta Tea Factory, Willie Group Tea Factory (Andaradeniya Estate Pvt Ltd), and Urubokka Tea Factory, we handled a variety of repairs including control board servicing, correcting camera misalignments, repairing feeder malfunctions, replacing touch screen panels, and resolving communication errors. Each of these interventions ensured that the Timing tea color sorters were restored to full operational capability.

The Challenge in Installation

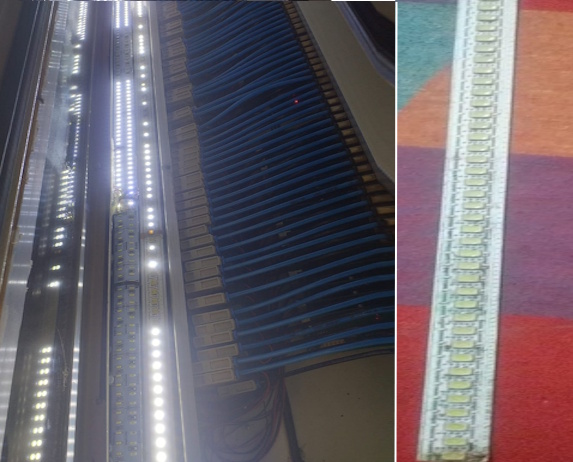

The greatest challenge in repairing Timing tea color sorters was dealing with machines that had operated continuously for years with limited preventive maintenance. This resulted in multiple failures occurring at the same time, such as unstable power modules, defective LEDs, feeder blockages, and display unit breakdowns. Diagnosing and addressing these issues required a methodical and detail-oriented approach to ensure no hidden faults remained.

Another key challenge was the difficulty of sourcing original spare parts for older Timing models. In many cases, the required parts were no longer readily available, which meant our team had to design and implement custom-engineered solutions to ensure proper integration and performance. Despite these hurdles, all repairs were carried out within tight time frames, allowing factories to continue their operations without major production interruptions.

"Our Timing tea color sorter had been causing repeated problems, from feeder issues to frequent shutdowns. Braintronic’s team repaired the machine quickly and professionally, and after the service, it performed as if it were new again. Their work not only fixed the problems but also restored our confidence in the equipment."

Factory Owner, Rasilta Tea Factory

The Final View of Project

By the conclusion of these projects, all Timing tea color sorters were brought back to stable, reliable, and high-precision performance. The repairs significantly reduced breakdown frequency, improved sorting accuracy, and provided factory owners with renewed assurance in their equipment. This directly translated into smoother workflows, better product quality, and uninterrupted production schedules.

These successful interventions once again highlighted our ability to deliver fast, dependable, and cost-effective repair solutions for Timing machines. By extending the lifespan of the equipment and restoring it to near-new condition, we helped factories maximize their investment while maintaining world-class standards in tea production.