50 + Full Restoration of Abandoned Coaire Compressors

Project Description

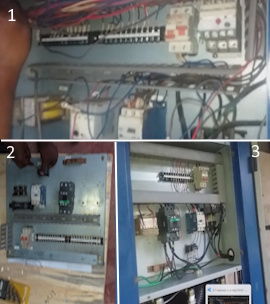

Our engineering team successfully completed several Coaire compressor repair projects across Sri Lanka, ensuring that machines were restored to peak efficiency and reliable operation. These projects focused on resolving issues such as air leakages, motor malfunctions, control panel errors, and preventive servicing to extend the life of the equipment. Each repair was carried out with the goal of minimizing downtime while securing long-term performance improvements for the factories.

These are only a few of our doings: at Urubokka Tea Factory and Fairy Mount Tea Factory, we performed comprehensive repairs including overhauling compressor units, servicing airend components, replacing worn-out bearings, correcting electrical faults, and carrying out full system testing. Each intervention ensured that the Coaire compressors returned to stable, uninterrupted operation, supporting continuous production in the factories.

The Challenge in Installation

The primary challenge in repairing Coaire compressors was dealing with systems that had run for extended periods without adequate preventive maintenance. This led to simultaneous failures such as overheating motors, degraded lubrication systems, and excessive vibration due to worn-out parts. Identifying and addressing these issues required careful inspection and technical expertise to restore full efficiency.

Another challenge arose with the availability of certain critical spares. Some original Coaire components were not readily available locally, requiring us to engineer customized solutions that matched performance standards. Despite these difficulties, our team managed to complete the work within strict deadlines, ensuring that tea production was not disrupted for long periods.

"Our Coaire compressor had been giving continuous trouble, affecting both air supply and production. Braintronic’s repair service restored the machine to excellent condition. Since the repair, we have not experienced a single breakdown, and production has been running smoothly. Their technical skill and commitment were outstanding."

Factory Owner, Urubokka Tea Factory

The Final View of Project

By the end of these projects, the Coaire compressors were restored to stable, efficient, and reliable operation. The repairs eliminated recurring problems, reduced energy losses, and ensured uninterrupted compressed air supply for production. This not only improved efficiency but also contributed to lowering operational costs for the factories.