Over 60 factories got AMD Tea Color Sorters repaired

Project Description

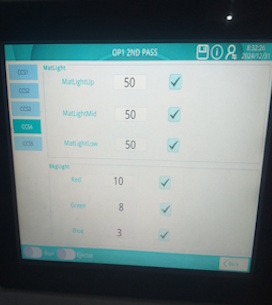

Our engineering team successfully completed multiple AMD tea color sorter repair projects across Sri Lanka, restoring the machines to their full accuracy and dependability. Each project was handled with a strong focus on minimizing downtime and ensuring that sorting efficiency was brought back to factory standards. The repairs included detailed inspections, replacement of defective modules, calibration of optical sensors, and fine-tuning of the control system to deliver consistent sorting results.

These are only a few of our doings: at Allenvally Tea Factory, where we repaired and serviced an AMD 5 Stage color sorter, and at Noori Tea Factory, where we carried out critical service and fault correction work. Each repair intervention was tailored to the unique condition of the machine, ensuring that both facilities could continue production without interruption and with renewed confidence in their sorting equipment.

The Challenge in Installation

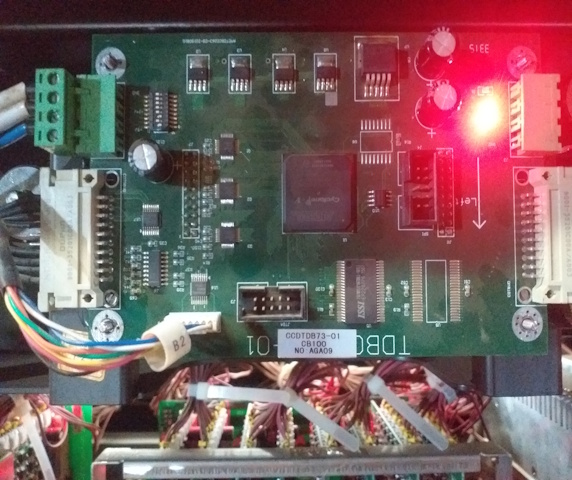

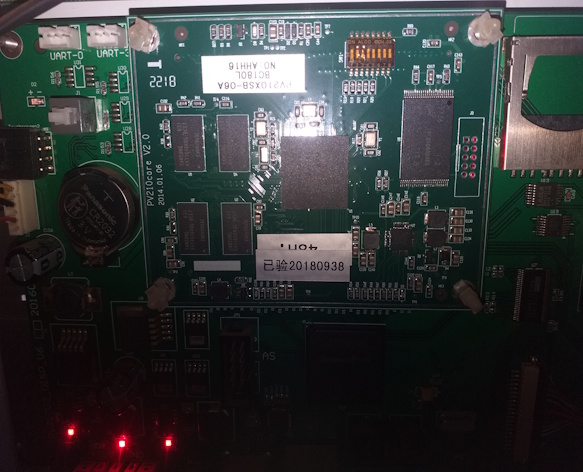

One of the key challenges in repairing AMD tea color sorters was the complex nature of multi-stage systems, which required a high degree of technical precision during troubleshooting. Machines that had been running continuously for long periods showed multiple faults, such as feeder malfunctions, unstable communication boards, sensor misalignments, and worn-out ejector valves. Each issue needed to be diagnosed in detail, often requiring simultaneous solutions to restore full working efficiency.

Another challenge was the availability of spares for AMD machines, particularly for older models that were still in operation at many tea factories. In several cases, original parts were either unavailable or faced long procurement times. Our engineers developed custom-engineered alternatives and carefully integrated them into the systems without compromising quality. Despite these hurdles, we completed the projects successfully within short timelines, enabling the factories to continue production with minimal downtime.

"Our AMD tea color sorter had been giving continuous trouble and was affecting the quality of our production. After Braintronic’s repair and service, the machine started working like a new one again. Their expertise and commitment were truly impressive, and they completed the job without causing unnecessary delays to our operations."

Factory Owner, Allenvally Tea Factory

The Final View of Project

By the end of these projects, the AMD tea color sorters were fully restored to stable, precise, and reliable operation. The machines achieved consistent sorting accuracy, reduced downtime, and provided factory owners with renewed confidence in their production lines. The improvements also led to smoother workflows and enhanced overall tea quality.

These projects once again demonstrated our ability to deliver fast, dependable, and cost-effective repair solutions for AMD machines. By extending the service life of existing equipment and restoring it to near-new condition, we helped tea factories achieve greater efficiency, reduced maintenance costs, and uninterrupted production schedules.