100 + Panel Board Repairs and Services

Project Description

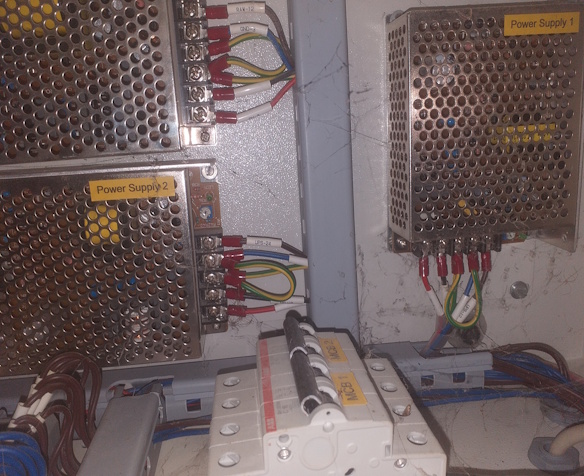

Our engineering team successfully completed several panel board repair projects in both tea factory machinery and rice mill systems across Sri Lanka. These repairs played a critical role in restoring electrical control systems that govern the smooth functioning of production equipment. Each project involved diagnosing faulty circuits, repairing or replacing damaged components, and reconfiguring control systems to ensure reliability and safety in operations.

These are only a few of our doings: at Urubokka Tea Factory, Fairy Mount Tea Factory, Daham Rice Mill, and Anamaduwa Rice Mill, we carried out comprehensive panel board repairs such as replacing damaged relays, servicing power modules, correcting wiring errors, repairing communication boards, and restoring automated control functions. Each intervention ensured that factory machinery and rice mill equipment returned to uninterrupted and dependable performance.

The Challenge in Installation

One of the main challenges in panel board repair was dealing with aged and overworked systems that had been running for years without proper preventive maintenance. Many panels had accumulated dust, moisture damage, and heat stress, which caused frequent tripping, voltage fluctuations, and communication failures between machines. Diagnosing these complex faults required systematic testing and careful rewiring to restore stability.

Another challenge was the unavailability of specific panel board components for older tea and rice mill machinery. Some boards had outdated configurations that were no longer supported by manufacturers. Our engineers designed customized replacements and rewiring solutions, ensuring compatibility with existing systems while maintaining performance standards. Despite these difficulties, we completed the work within strict timelines, minimizing downtime for production facilities.

"Our factory panel board had frequent faults that disrupted production. The Braintronic team quickly identified the problems, repaired the circuits, and restored the system to full working order. Since their repair, we have not experienced any unplanned shutdowns, and the operation has been running smoothly."

Factory Owner, Urubokka Tea Factory

The Final View of Project

By the end of these projects, the repaired panel boards provided stable, safe, and efficient control of tea factory machines and rice mill equipment. The improvements significantly reduced downtime, improved safety standards, and ensured uninterrupted production schedules for the factories. Owners reported higher operational confidence and smoother workflow across their facilities.