Full Restoration of Abandoned Jaguar Compressor

Project Description

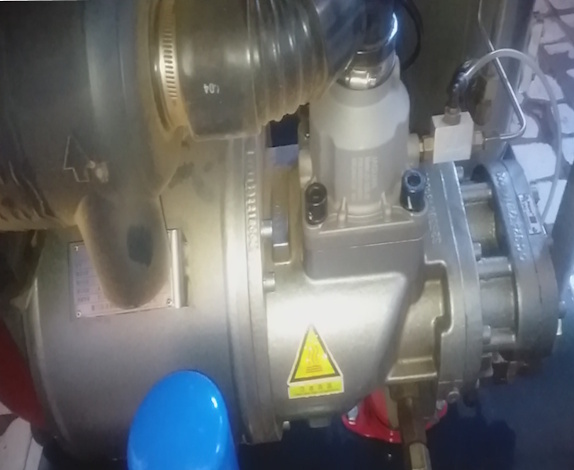

Our team successfully completed a series of Jaguar compressor repair works across Sri Lanka, ensuring these vital machines were restored to peak operating condition. Jaguar compressors played a key role in powering tea processing machinery, and their proper functioning was essential to uninterrupted production. Each project was handled with care, using detailed inspections, replacement of worn components, and fine-tuning of the system to achieve maximum efficiency.

Highlights of our work included the Jaguar compressor repair at Uruwala Tea Factory. This was only one among several repair projects we undertook, showcasing our expertise and commitment to providing reliable solutions for factory operations. By combining skilled technical knowledge with genuine parts, we delivered lasting improvements to compressor performance and helped reduce operational downtime.

The Challenge in Installation

During these repairs, one of the main challenges we faced was diagnosing deep-rooted mechanical and electrical faults that had developed over years of continuous usage. Compressors in tea factories often operated under high demand, which caused components to wear out faster and reduced efficiency. Locating these underlying issues required a combination of advanced diagnostic tools and hands-on experience.

Another major challenge was minimizing downtime for the factories during the repair process. Since Jaguar compressors powered critical equipment, any extended breakdowns directly affected tea processing. Our team had to plan and execute repairs swiftly, sometimes working under time constraints, to ensure the factories resumed normal operations without significant production losses.

"Our Jaguar compressor had been a recurring issue for some time, causing delays in our production line. The repair carried out by this team was remarkable. They quickly identified the problems, carried out the necessary replacements, and restored the compressor to full working condition. The factory experienced an immediate improvement in performance after their intervention."

Factory Owner, Uruwala Tea Factory

The Final View of Project

At the completion of these projects, the repaired Jaguar compressors delivered stable performance that met the daily demands of tea factory operations. Energy efficiency improved significantly, which reduced overall running costs for the factories. In addition, the compressors were operating smoothly with minimal vibration and noise, which added to the overall workplace comfort and safety.

"571" height="465" style="display: block; object-fit: cover; border-radius: 8px;">

"571" height="465" style="display: block; object-fit: cover; border-radius: 8px;">