Over 60 factories got Piston Compressors Repaired

Project Description

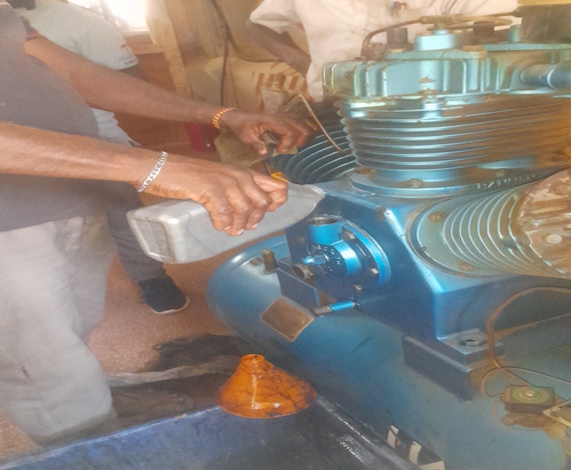

Our team successfully carried out repair and restoration work on piston compressors, ensuring these critical machines were restored to dependable working condition. Piston compressors play a vital role in providing compressed air for tea factory operations, and their efficiency directly affects production output. The repair process involved thorough fault detection, replacement of defective parts, and performance tuning to bring the compressors back to peak efficiency.

A highlight of our work was the piston compressor repair at Kirkaswald Tea Factory. This project reflected our ability to diagnose problems quickly, supply genuine replacement parts, and execute the repairs with minimal disruption to factory operations. By applying both technical expertise and industry experience, we ensured that the piston compressor functioned reliably, delivering uninterrupted air supply to support the factory’s tea processing activities.

The Challenge in Installation

The repair process came with several challenges that required specialized solutions. One of the main issues was excessive wear in the moving parts of the piston compressor, which caused irregular pressure output and overheating. Detecting these faults required careful inspection and dismantling, followed by precise alignment and fitting of new parts to ensure proper functionality.

Another challenge was balancing the repair work with the factory’s production schedule. The Kirkaswald Tea Factory relied heavily on its compressor for daily operations, and any downtime had to be minimized. Our team coordinated closely with the management to complete the repairs efficiently, restoring the system within a short timeframe and avoiding major production delays.

"Our piston compressor had been giving us trouble for several months, and it was affecting our production. The repair team handled the project with great skill and professionalism. They identified the root causes of the breakdown, replaced the faulty components, and ensured the machine was running smoothly again."

Factory Owner, Kirkaswald Tea Factory

The Final View of Project

By the end of the project, the piston compressor at Kirkaswald Tea Factory was fully restored to operational condition. The system delivered consistent air pressure, which stabilized production lines and improved efficiency across the factory. The repaired compressor also consumed less energy, helping reduce operational costs while maintaining reliable performance.